Axcyl

Axcyl sleeve

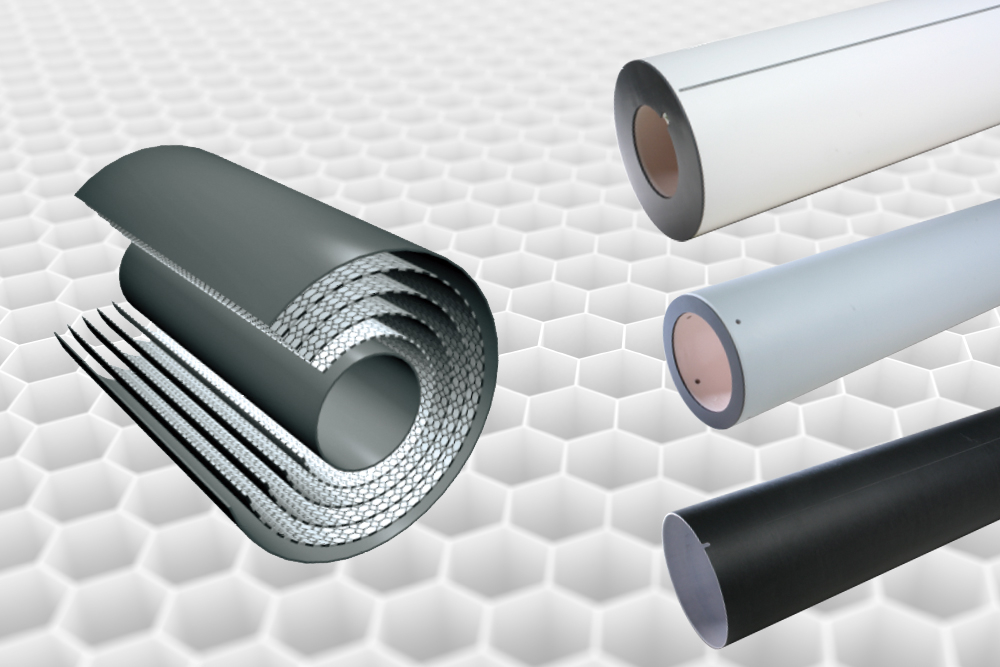

Axcyl offers a sleeve technology to assist flexographic wide web and narrow web printers for printing on any type of substrates.

Coaxcyl EM

Equipped with optional patented cutting guide

Advantages

- Extended product life:

- Totally sealed sleeve, preventing from solvent & ink penetration, compatible with sleeve cleaning machines

- Shock absorbing faces, preventing from premature edge damages Patented cutting guide

- Reinforced register slot from any sleeve thickness(Carbon/Kevlar, or metal insert)

- Vibration filtration, thanks to damping mounting layer

- Honeycomb structures enables high rigidity and extremely low density

COAXCYL BS

Trelleborg Coaxcyl BS flexo sleeve

Advantages

-

Covers wide repeat range on one shaft

Minimize capital spending

- Extended product life:

- Totally sealed sleeve, preventing from solvent & ink penetration, compatible with sleeve cleaning machines

- Shock absorbing faces, preventing from premature edge damages

- Reinforced register slot with bayonet system and pin index

- Possibility of separated air supply for top sleeve mounting

- Vibration filtration, thanks to damping mounting layer, reducing press bounce

- Honeycomb structures enables high rigidity, and extremely low density

AXCYLOX Sleeves

Features and benefits:

-

Anilox is an essential part of the flexo printing process. Its ceramic outer layer is extremely hard, but fragile. Axcylox sleeve is designed to cover & protect the Anilox during all operations, apart from printing.

- Rough outer surface, for excellent manual handling

- Machined hole, to ease removal of anilox + Axcylox on press

- Smooth inner surface, for easy cleaning

- Rubber edge, to immobilize the Axcylox on the anilox, and protect the anilox face

- Permanent label for tracability & identification (with indication of anilox color, volume & screen ruling)

The end result is a permanent protection of the fragile outer surface of the Anilox, increasing its life span and reducing costly repairs due to damages.